Fiberglass Pool Manufacturing and Design

Mold Preparation

The mold is cleaned to ensure it is in perfect condition before pools are made. All pool fittings are applied and recorded.

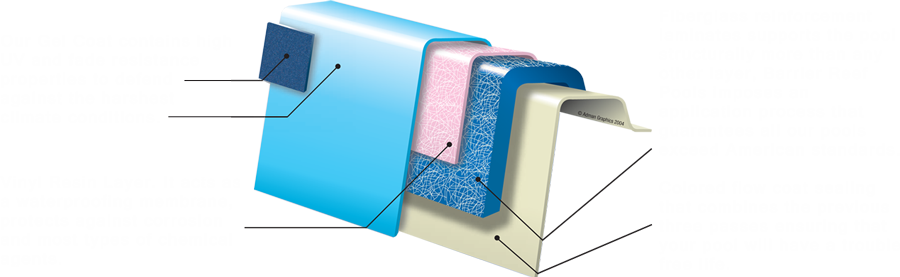

Gelcoat Application

This stage consists of three passes of gelcoat sprayed onto the mold. The mold is left for a short time between each spray. Each stage of gelcoat application has to pass the stringent quality control criteria by Construction Management before proceeding to the next stage.

Epoxy Vinyl Ester Application

This product is sprayed onto the gelcoated mold to give the pool its waterproof quality. It is measured and accurately applied to match the surface area of each pool size being made. The product is then left to cure before being checked once more by quality control. It is then ready to move to the final phase of the manufacturing process.

Fiberglass Re-Lamination

The first layer of fiberglass is applied as a “skin”. Once the skin stage has been completed, the pool then undergoes a reinforcing stage, with the application of Klegcell PVC close cell foam.

Lifting lugs are then applied. Lifting lugs enable the pools to be lifted by crane for transportation.

At the Reo Stage, another layer is applied to cover all work and to provide a final stage of reinforcing.

The pool making process has now been completed. Barrier Reef Pools is committed to maintaining a very high standard of fiberglass swimming pool. Each pool has a corresponding manufacturer sheet to ensure that the correct amount of quality materials has been used in every pool. Research and development in conjunction with our suppliers is a very high priority within our company, and helps to ensure that our products are always modern and unique.

Only the Best Design & Manufacturing Processes